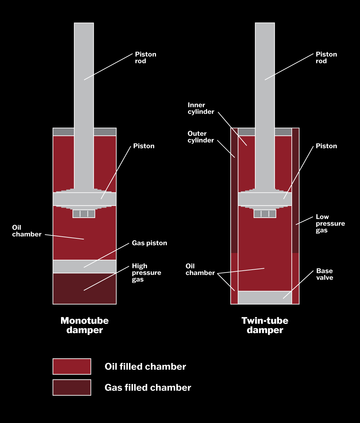

Figure 1: A comparison between the design of a monotube damper and a twin-tube damper.

A monotube damper, also known as a monotube shock absorber, is a type of hydraulic suspension component commonly used in automotive applications. Its design consists of a single tube that houses all the essential components required for damping.

How does a monotube damper work?

Hydraulic Fluid and Piston Assembly: Inside the monotube damper, there's a chamber filled with hydraulic fluid. A piston assembly, typically consisting of a piston and piston rod, is located within this chamber. The piston is designed with multiple ports or valving to control the flow of hydraulic fluid.

Compression and Rebound Stages: When the vehicle encounters a bump or dip in the road surface, the suspension system compresses or extends, causing the wheel to move upward or downward. During compression, the piston moves through the hydraulic fluid, compressing it against the fluid in the reservoir. This action generates resistance, dampening the upward movement of the suspension and controlling the rate at which the wheel moves.

Heat Dissipation: Monotube dampers are efficient at dissipating heat generated during compression and rebound. The single-tube design allows for better heat dissipation compared to twin-tube dampers, which have an outer shell that can trap heat. This efficient heat dissipation helps maintain consistent damping performance under various driving conditions.

Gas Charge: Supashock monotube dampers incorporate a high pressure nitrogen gas charge, above the hydraulic fluid. This gas charge is separated from the hydraulic fluid by a gas piston, which to helps prevent aeration of the hydraulic fluid, ensuring consistent damping performance and minimizing foaming, which can significantly degrade damping efficiency (the common downfall of twin-tube dampers).

External Reservoir (Optional): In some high-performance applications, monotube dampers may feature an external reservoir. This reservoir allows for additional fluid capacity and provides more precise tuning of damping characteristics. It also helps reduce the operating temperature of the hydraulic fluid, further enhancing performance and durability.

Adjustability: Many monotube dampers are designed with adjustable features, such as external rebound or compression damping adjustments. These adjustments allow drivers or suspension tuners to fine-tune the damping characteristics to suit specific driving conditions, preferences, or vehicle setups.

A monotube damper operates by utilizing hydraulic fluid and a piston assembly to control the movement of the suspension system, providing damping force to manage vehicle motion. Its single-tube design offers efficient heat dissipation and, in some cases, allows for adjustability to optimize performance for different driving scenarios.