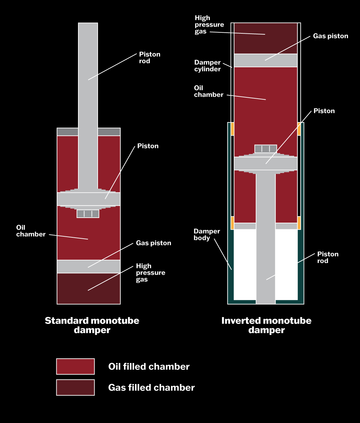

Figure 1: A comparison between the design of a standard monotube damper and an inverted monotube damper.

An inverted monotube damper is a specialised type of shock absorber commonly used in high-performance automotive applications, particularly in racing and sports cars. It shares similarities with conventional monotube dampers but features a distinct inverted design, where the piston assembly is located at the bottom of the damper instead of the top. Here's how an inverted monotube damper works:

Inverted Design: In an inverted monotube damper, the piston assembly is situated at the bottom of the damper, attached to the end of the piston rod. This design inversion offers several advantages, including reduced unsprung weight, improved heat dissipation, and better protection of internal components from contaminants like dirt and debris.

Hydraulic Fluid and Piston Assembly: Similar to conventional monotube dampers, the inverted monotube damper contains a chamber filled with hydraulic fluid. The piston assembly, comprising a piston and piston rod, moves within this chamber. As the wheel encounters bumps or road imperfections, the suspension compresses or extends, causing the piston assembly to move through the hydraulic fluid.

Compression and Rebound Stages: During compression, as the wheel moves upward, the piston assembly compresses the hydraulic fluid against the fluid in the reservoir. This action generates resistance, dampening the upward movement of the suspension and controlling the rate at which the wheel moves. Conversely, during rebound, as the wheel moves downward, the piston assembly extends, allowing hydraulic fluid to flow back into the main chamber, regulating the extension of the suspension.

Heat Dissipation: The inverted design of the monotube damper allows for efficient heat dissipation. Heat generated during compression and rebound dissipates through the exposed outer surface of the damper, preventing heat buildup that can affect damping performance. This capability is particularly crucial in high-performance driving scenarios where consistent damping is essential.

Gas Charge and External Reservoir: Supashock inverted monotube dampers incorporate a high-pressure nitrogen gas charge, above the hydraulic fluid, and is separated by a gas piston to prevent aeration and maintain consistent damping performance. Additionally, high-performance applications may feature an external reservoir to provide extra fluid capacity and further enhance damping control and heat dissipation.

Adjustability: Like conventional monotube dampers, inverted monotube dampers may offer adjustability features such as external rebound or compression damping adjustments. These adjustments allow for fine-tuning of damping characteristics to suit specific driving conditions, preferences, or vehicle setups.

Inverted monotube dampers operate similarly to conventional monotube dampers but feature an inverted design for improved performance and durability in high-performance automotive applications. Its efficient damping, heat dissipation, and potential for adjustability make it a preferred choice for demanding driving scenarios where precise control of vehicle dynamics is paramount.