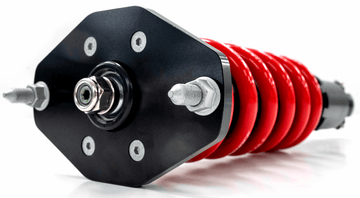

A locking collar, commonly employed in cars and various industrial applications, is a mechanical device designed to securely fasten components onto a shaft and serve as an efficient means of positioning, transmitting motion, preventing bearing slippage, and maintaining separation between items attached to the shaft.

Locking collars find extensive utilisation across multiple sectors, including agriculture, plant operations, automotive manufacturing, and light to heavy industrial machinery.

When it comes to cars, these collars play a vital role in keeping bearings in position on shafts, ensuring optimal performance and longevity. Moreover, they enable the precise positioning of shafts, contributing to the accurate alignment of various mechanical elements within a system. Additionally, locking collars are utilised to keep items separate on shafts, preventing any unwanted contact or interference between different components.

What are the benefits of locking collars?

Secure fastening

Locking collars provide a secure attachment of components to the shaft, ensuring that they remain firmly in place even under extreme conditions such as vibrations, shocks, or sudden changes in direction. This helps to prevent loosening or disconnection of critical parts, maintaining the integrity of the automotive system.

Bearing positioning

Locking collars play a vital role in keeping bearings in the correct position on the shaft. Proper bearing alignment ensures smooth rotation and reduces friction, resulting in enhanced performance and longevity of the bearings.

Shaft alignment

Precise positioning of the shaft is crucial for optimal operation and efficiency of various mechanical elements in a car. Locking collars enable accurate alignment, ensuring that the shaft is correctly positioned within the system, minimising any potential misalignment issues that could lead to excessive wear, noise, or reduced performance.

Component separation

Locking collars are used to keep different components separate on the shaft, preventing unwanted contact or interference. This helps to avoid potential damage, wear, or malfunction caused by components rubbing against each other.

Improved durability

By securely fastening components and preventing slippage, locking collars contribute to the overall durability and reliability of automotive systems. They reduce the risk of component failure, ensuring consistent performance over the lifespan of the vehicle.

How are locking collars installed?

Locking collars are typically installed using the following steps:

-

Preparation

Gather the necessary tools and equipment for the installation process. This may include wrenches, socket sets, or other specialised tools depending on the specific type of locking collar being used.

-

Shaft Preparation

Ensure that the shaft is clean, free from debris, and properly sized to accommodate the locking collar. If needed, remove any existing components or old collars from the shaft.

-

Positioning

Determine the desired position along the shaft where the locking collar will be installed. Take into consideration the specific requirements of the application, such as bearing placement or component separation.

-

Placement

Slide the locking collar onto the shaft at the desired position. Ensure that the collar is oriented correctly, with any set screws or locking mechanisms facing the appropriate direction for easy access during installation and future maintenance.

-

Tightening

Using the appropriate tools, tighten the locking collar onto the shaft. This typically involves tightening the set screws or locking mechanisms to secure the collar in place. Follow the manufacturer's guidelines regarding the recommended torque specifications to ensure proper installation.

-

Double-Checking

After tightening the locking collar, double-check the tightness and stability of the installation. Ensure that the collar is securely fastened and there is no excessive play or movement between the collar and the shaft.

-

Testing

Once the locking collar is installed, perform a test to ensure that it is functioning correctly. This may involve rotating the shaft or applying pressure to the connected components to verify that the collar effectively prevents slippage or unwanted movement.

It is important to consult the specific instructions provided by the manufacturer of the locking collar being used, as installation methods may vary depending on the design and type of collar. Adhering to the manufacturer's guidelines will help ensure a proper and secure installation.

Maintenance and Care for Locking Collars: Keeping Them in Top Condition

Locking collars require proper maintenance and care to ensure optimal performance. Regular cleaning is necessary to remove dirt and debris that can hinder their functionality.

Additionally, conducting routine inspections helps identify signs of damage or misalignment, enabling timely repairs or replacements. By addressing these maintenance needs, locking collars can securely fasten components, maintain proper bearing positioning, ensure accurate shaft alignment, and prevent unwanted component interference.

This not only enhances the durability and reliability of automotive systems but also contributes to improved overall performance and longevity.